Vexta Stepping Motor Nema 23

- 4.5v dc

- 2a

- 1.8degree/step

- 6 wire.

- Bipolar

High Resolution Type

These 2-phase, high resolution stepping motors have half the

step angle of standard stepping motors. The high resolution

type increases motor resolution from 200 steps/revolution to

400 steps/revolution. Smaller step-angles can be achieved

by half-step driving or microstep driving. Such options,

however, do not improve accuracy. Other than having twice

as many rotor teeth as standard stepping motors, all other

structures are exactly the same as the standard motors.

SH Geared Type Nema 23

Incorporating SH gears with high permissible torque, these

models offer the full benefit of the speed reducing capability

of geared motors, delivering high resolution, high torque and

smooth low-speed rotation. With performance like this, the

SH Geared type can easily satisfy the requirements of

various kinds of low-speed positioning applications.

Smooth Rotation at Low Speeds

Stepping motors at low speed produce a relatively high

amount of vibration. Use of a gearhead allows for an

increase in the speed of the motor which results in a

smoother motion while maintaining the low output speed

required by the application.

Six Gear Ratios Nema 23

SH geared motors are available with six different gear ratios:

3.6:1, 7.2:1, 9:1, 10:1, 18:1, 36:1. The low ratios of these

gearheads can greatly facilitate speed control of the 2-phase

stepping motors.

✽ PK223-SG type is not available in a gear ratio of 3.6:1.

Ideal for High Inertia Drive

The stepping motor itself can drive an inertia of 10 times the

rotor inertia. The geared type can reduce the load inertia by

the square of the gear ratio. Therefore, the geared type is

suitable for driving larger inertial loads.

High Inertia Capability

The PV Series provides, on average, 1.5 times higher torque

than a standard stepping motor. By utilizing a larger rotor

diameter, larger magnets can be used to significantly

increase the output torque.

PV Series

Angle–Torque Characteristics

All equipment has a friction load, and the motor stops when the motor output

torque and friction load torque are balanced. As shown in the characteristics

above, the larger the output torque per step angle, the less the motor is influenced

by the friction load, so positioning accuracy is improved. Stop positioning

displacement by external force does not occur as often.

Pulse Speed [kHz]

0 0.5 1.0 1.5 1.8°/step

100 200 300 400 500

Speed [r/min]

Torque [oz-in]

0

300

200

500

400

100

PV Series PV269-D2.8BA: Bipolar 2.8 A/Phase, 24 VDC

Standard PK296-E4.5B:

Bipolar (series) 3.18 A/Phase, 24 VDC

Standard PK268-E2.0B:

Bipolar (parallel) 2.8 A/Phase, 24 VDC

0

2.0

3.5

3.0

2.5

1.5

1.0

0.5

Torque [N·m]

Related products

Breakout Boards & Modules

CNC & 3D Printer Parts

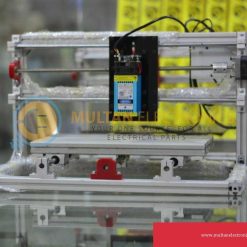

CNC 3018,DIY Engraving Machine 15W 450nm laser engraving GRBL control

CNC & 3D Printer Parts

CNC & 3D Printer Parts

CNC & 3D Printer Parts

40/80/120/160/200/280/320 Thermoelectric Cooler Peltier Aluminium Water Block

CNC & 3D Printer Parts

CNC & 3D Printer Parts

Stepper Motor 5V DC 4-Phase 5-Wire with ULN2003 Driver Board

CNC & 3D Printer Parts

10mm Screw Rod M10 Threaded Rod For CNC Machine And 3D Printer